The meat and poultry industry are the most efficient industries in the world. They are able to deliver great products in a safe and cost efficient way. Changing consumer demand requires flexible and continuously adapting of the products. We are looking for ways to help you to differentiate. To stay relevant with new and exciting concepts that fit in your production set-up.

Reduce energy consumption and increase the capacity of your process. With our injection solutions, we can reduce the cooking time of slow cooked meat up-to 75%, without compromising on the texture of your end product.

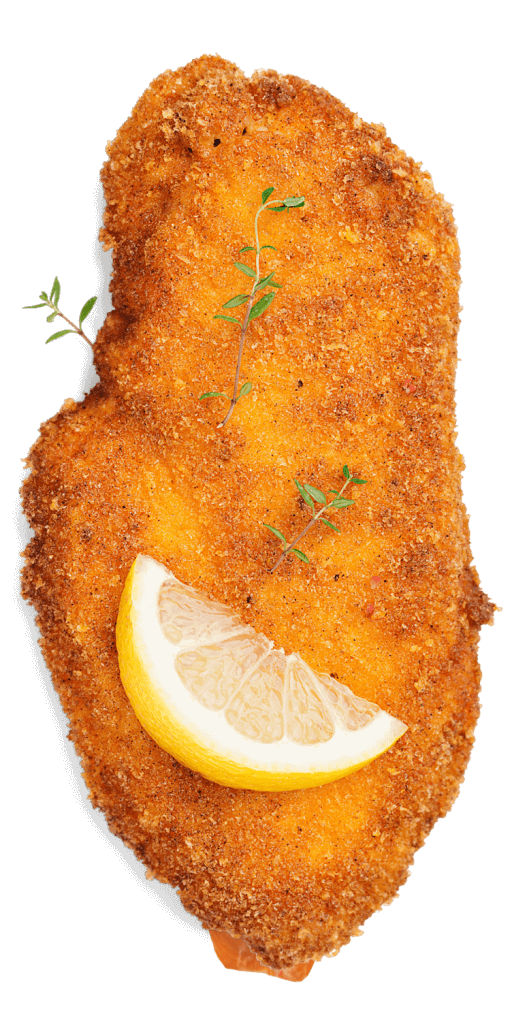

Consumers increasingly consume pre-cooked meat. Many of your customers demand that your products are cooked to a core temperature of 82 degrees Celsius. We bring the yield on green weight to 100% with the help of clean label brines. Besides the economic advantages, we ensure that you have a great-tasting juicy product.

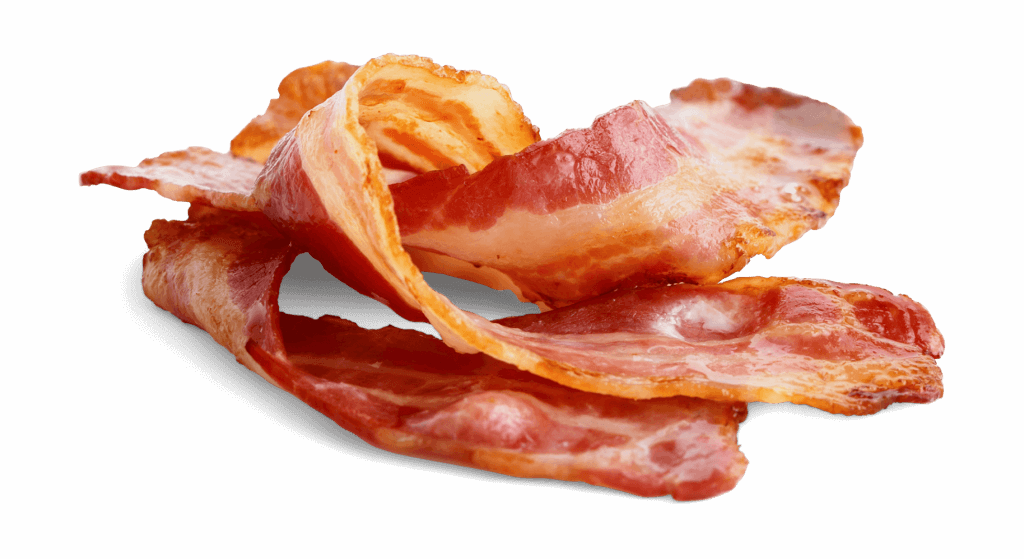

There is growing concern about the use of nitrite in meat products. With our solution, we can replace nitrite in bacon. We do not work with extracts or nitrate sources, and we create the right colour using cultures and the right curing process.

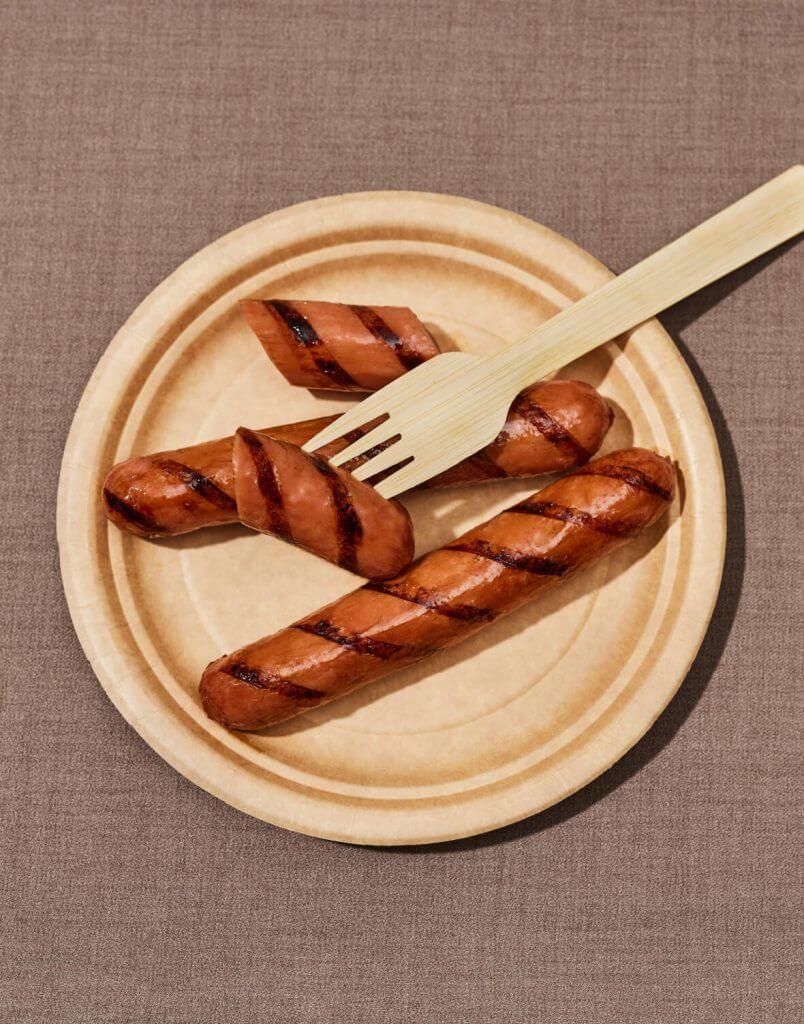

There is a growing demand for eating products on-the-go. Adding poultry to a salad or a sandwich looks great and gives a nice texture, but it often lacks a distinct taste. We can enhance the real taste of chicken in a clean label way. By adding a cooking profile and the right colour you can simplify your process; a grilled chicken appearance, but prepared in a steam cooker!